- Time : Monday-Saturday 09am-6pm

- (+91) 8925886265

Cleantek electrostatic Oil Mist Collectors are specialized devices designed to effectively remove oil mist, fumes, and particulates generated during machining, metalworking, and other industrial processes. These collectors are crucial in maintaining a clean and safe working environment while preserving machinery and tools.

Cleantek Oil mist collectors are essential for maintaining a clean and safe working environment in CNC machine shops. These collectors help in removing airborne oil mist, coolant mist, and other particles produced during machining operations.

Cleantek Oil Mist Collector for CNC Machines:

CNC machining processes often generate potentially harmful oil mist and airborne particles, which can pose significant health risks to employees and increase maintenance challenges for machines. Cleantek advanced Oil Mist Collector effectively collects, purifies, and controls oil mist, ensuring a safe and productive working environment in industries like turning, milling, drilling, and wet grinding.

Key Benefits and Features:

Health and Safety:

Efficiency and Performance:

Durability and Maintenance:

Why Choose Cleantek Oil Mist Collectors?

Cleantek oil mist collectors ensure cleaner air quality, reduced health risks, and increased productivity in CNC machining environments. By addressing both employee safety and machine efficiency, Cleantek delivers a comprehensive solution to industrial air pollution challenges.

For reliable and efficient oil mist management, Cleantek Made in India oil mist collectors are the ideal choice, offering superior filtration technology, ease of maintenance, and robust build quality.

Filtration Efficiency: Cleantek Oil mist collector with high-efficiency filters capable of capturing small particles effectively. HEPA (High-Efficiency Particulate Air) filters or specialized mist filters or ESP filters are used. This mist collector has adequate airflow capacity to handle the volume of mist produced by your CNC machines. Our mist collector is compact collector, prioritize units designed to fit in limited spaces without compromising efficiency. Our mist collector filters easy clean and washable. Some of our mist collector model fitted with washable or longer-lasting filters.

Low noise generated by the collector as it operates, especially if the CNC machines are in a noise-sensitive environment. We offer additional features such as variable speed controls, automatic monitoring, and alarms for filter replacement or system malfunctions.

Capture: The polluted air containing oil mist is drawn into the collector unit through an intake mechanism.

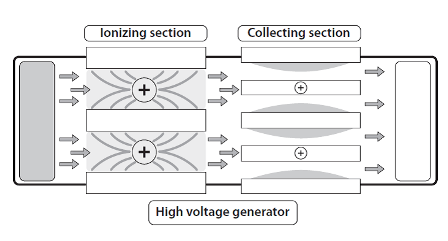

Ionization: Inside the collector, the air passes through a series of ionization wires or plates. These wires or plates are charged with a high voltage, typically in the range of several thousand volts. As the air passes through this ionization zone, the oil mist particles in the air become electrically charged.

Attraction: The charged oil mist particles are then attracted to a collection surface, usually made of metal plates or tubes, which carry the opposite electrical charge. This attraction is due to the principle that opposite charges attract each other.

Collection: Once the oil mist particles are attracted to the collection surface, they adhere to it and are effectively removed from the air stream. Over time, these particles accumulate on the collection surface and form a layer of oil, which can be periodically cleaned or drained from the unit.

Clean Air Release: The now-cleaned air is then released back into the environment, significantly reducing the concentration of oil mist particles and improving air quality. This process effectively removes oil mist from the air using electrostatic forces, making it an efficient method for industrial applications where oil mist pollution is a concern, such as metalworking, machining, and other manufacturing processes.

.jpeg)

Cleantek design and manufacturing mechanical / electrostatic Oil Mist Collection systems for CNC machine oil fume killer and fine mist collection. We are the well known company manufacturing Oil Mist Collector Manufacturers in India to extract the oil smoke and coolant mist.

By removing oil mist and particulates from the air, these collectors significantly enhance indoor air quality, creating a safer and healthier working environment for employees.Minimizing the accumulation of oil mist on machinery and tools helps prolong their lifespan and reduces maintenance costs.Minimizing the accumulation of oil mist on machinery and tools helps prolong their lifespan and reduces maintenance costs.These systems aid in complying with environmental and occupational health regulations by reducing emissions and maintaining a clean workspace.

Cleantek Oil Mist Collectors are specialized devices designed to effectively remove oil mist, fumes, and particulates generated during machining, metalworking, and other industrial processes. These collectors are crucial in maintaining a clean and safe working environment while preserving machinery and tools.

SN | Parameters | MODEL FE100ES |

1 | Motor | 0.75 kw |

2 | Voltage / Hz | 415 V/ 50 Hz |

3 | Airflow | 1000 m³/Hr |

4 | Filtration Stage | Pre Filter Fine Filter Electrostatic filter Activated carbon filter |

5 | Filtration Efficiency | 99 % |

6 | Duty | Continous duty |

7 | Suction inlet | Ф 100 mm |

8 | Insulation class | F |

9 | Motor protection | IP 55 |

Case Study: Cleantek CNC Oil Mist Collector Installation at Camshaft Manufacturing Company, Bangalore:

A leading camshaft manufacturing company in Bangalore, specializing in high-quality automobile camshafts, faced a significant challenge due to the widespread oil mist generated during their production processes. This oil mist, caused by metalworking fluids used in milling, turning, grinding, and drilling, posed a serious hazard in the workplace. Not only did it create a greasy and unsafe environment, but it also contributed to health issues among the operators, such as eye and skin irritation, shortness of breath, and potential respiratory problems.

Recognizing the urgency of the situation, Cleantek was approached to provide a solution. After conducting a thorough study of the company's manufacturing processes and the oil mist problem, Cleantek recommended and installed their Electrostatic Precipitator model oil mist filtration system.

This advanced filtration system effectively controlled 100% of the oil mist, preventing its spread into the workplace atmosphere. The benefits were immediate:

Thanks to Cleantek's solution, the company not only met its safety standards but also improved overall operational efficiency. The employees expressed their satisfaction with the new system, which has become an integral part of their daily operations.