- Time : Monday-Saturday 09am-6pm

- (+91) 8925886265

Cleantek industrial centrifugal blower fan is a device used to move air or gas in industrial settings. It operates based on the principle of centrifugal force.When the fan blades rotate, they draw air in and accelerate it outwards using centrifugal force. This force is created as the air is pushed away from the center of rotation, increasing its velocity.

We are the high quality centrifugal blower manufacturers in Coimbatore and we are supplying our blowers to Chennai, Bangalore, Hyderabad, Pune etc…… Cleantek is an ISO 9001 company following quality standards and BIS standards to produce the cleaning equipments. Cleantek centrifugal fan manufacturing and testing with guidance of Indian standard ae per IS 4894 : 1987.

Centrifugal blower is a electro mechanical equipment and convey the air fluid from one place to another place. Centrifugal blowers is widely used in dust control, ventilation, cooling,parts drying, parts cooling, hot air drying etc... Many industries required move the air or gas from one place to another place and here blowers are helps are use to here.Blower consist electrical motor, Impeller fan and fan housing . Air volume is depends upon the system connected with blower and load resistant. Forward curve Impeller, reverse curve impeller and straight leaf impeller etc.. are used to design the required volume and pressure in air blowers.

Cleantek is a renowned company recognized for its expertise in manufacturing air blowers and ventilation solutions. Their air blowers cater to a diverse range of industries and applications, offering efficient and reliable air movement technologies that are integral in various processes.

cleantek's line of air blowers encompasses a wide spectrum of designs, from centrifugal to axial, catering to different airflow requirements and pressure ranges. These blowers are engineered with precision to deliver optimal performance while ensuring energy efficiency and durability.

One of the key strengths of cleantek's air blowers is their versatility. Whether it's for industrial applications, such as pneumatic conveying systems, drying, cooling, or ventilation purposes in commercial buildings, cleantek blowers are designed to meet specific demands efficiently.

Their commitment to innovation and technological advancements has enabled cleantek to stay at the forefront of the industry. They continuously research and develop new methods to enhance blower performance, noise reduction, and energy efficiency. Additionally, their dedication to quality control ensures that each blower leaving their fcleanteklities meets stringent standards, ensuring reliability and longevity. Cleantek doesn't just provide standard solutions; they also offer customization options, tailoring blowers to suit unique requirements. This flexibility has made them a preferred choice for businesses seeking tailored air movement solutions.

Moreover, the company emphasizes environmentally friendly practices, striving to create products that minimize environmental impact. Their eco-conscious approach aligns with the growing demand for sustainable solutions across industries. Cleantek's commitment to customer satisfaction extends beyond just delivering products.

Cleantek team of experts provides excellent customer support, offering guidance from selection to installation and ongoing maintenance. This comprehensive approach has earned them a reputation for not just selling blowers but also providing reliable support throughout the product lifecycle.

Cleantek stands as a leader in the air blower industry, known for its innovation, reliability, and dedication to customer service. Their products play a crucial role in various sectors, driving efficiency and performance across different applications while maintaining a focus on sustainability and environmental responsibility. Cleantek manufacturing custom made model blower as per clients requirements.

CLEANTEK is an ISO certified company manufacturing all kind of centrifugal blower in various size. Centrifugal blower used in ventilation, combustion, transporting materials, cooling and heating systems, dust control, and air conveyor systems.These fans are particularly suitable for extraction of polluted air environment like cement factories, Textile mills,Pharmaceuticals plants,Steel mills,Packaging industries, Paper mills, foundries extra. Centrifugal Blower Fan Capacity available from one hundred to 35000 cubic meter per hour.

A centrifugal blower is an essential component in many industrial applications, offering superior efficiency and reliability. These blowers operate by drawing air into the center of a rotating impeller, which then accelerates and directs the air outward at high velocity. This process creates high-pressure airflow, making centrifugal blowers ideal for applications such as ventilation, cooling, and material handling. Cleantek centrifugal blowers are designed to enhance machine performance, improve air quality, and support energy-efficient operations.

With a focus on eco-friendly and high-quality products, Cleantek provides solutions that meet the rigorous demands of industrial maintenance and environmental standards. Invest in Cleantek’s centrifugal blowers for reliable, high-performance air movement and ensure optimal operation of your industrial systems. Visit Cleantek India to explore our range of centrifugal blowers and other industrial maintenance solutions.

Cleantek is a trusted manufacturer of industrial blowers, offering a wide range of air-moving solutions for various industrial applications. We design and manufacture low-pressure, medium-pressure, high-pressure, axial, and textile application blowers, ensuring optimal performance for different industries.

✅ Capacity from 0.5 HP to 50 HP – Wide range of power options.

✅ Custom-Made Blowers – Tailored solutions for specific applications.

✅ Energy-Efficient Design – Low power consumption with high airflow.

✅ Durable & Reliable – Made with high-quality materials for long-lasting performance.

✅ Quick Service & Spare Parts Availability – Fast after-sales support across India.

🔹 Low-Pressure Blowers – Ideal for ventilation, drying, and cooling applications.

🔹 Medium-Pressure Blowers – Used in industries requiring moderate airflow with controlled pressure.

🔹 High-Pressure Blowers – Designed for applications needing strong suction and discharge power.

🔹 Axial Blowers – Best for high-volume air movement in large areas.

🔹 Textile Application Blowers – Specialized blowers for lint removal and air circulation.

🔹 Custom-Made Blowers – Designed as per customer requirements for unique applications.

✅ Textile Industry – Lint removal and air circulation in mills.

✅ Food Processing – Ventilation and cooling for hygienic operations.

✅ Foundries & Metal Processing – Dust and fume extraction.

✅ CNC & Machine Shops – Oil mist and dust control.

✅ Chemical & Pharma Industry – Safe air handling for production processes.

✅ HVAC & Ventilation – Efficient air circulation in large spaces.

Feature | Cleantek Industrial Blower | Imported Brands |

|---|---|---|

Manufacturing | Made in India – Customizable | Imported – Limited customization |

Price | Cost-Effective | Expensive due to import duties |

Service Support | Fast & Local | Delayed service & spare parts |

Spare Parts | Readily Available | Difficult to procure |

Customization | Available | Limited to standard models |

MODEL | Direct Drive Centrifugal Blower | |

Sl.No |

Description of details |

CB0.5HF |

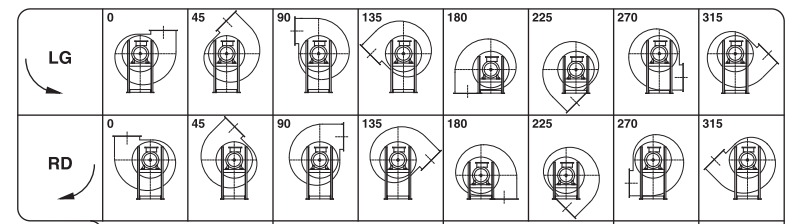

1 | Blower direction | RD-0 |

2 | Rpm | 2880 |

3 | Ph/Volt | 3 / 415V |

4 | Hp/Kw | 0.5 / 0.37 |

5 | Current | 1.4A |

6 | Inlet Pressure in (kpa) | -0.4 |

7 | Inlet Pressure in (mm of wg) | 40 mm of wg |

8 | Inlet airflow (cmh) | 514 m³/ hr or 276 CFM |

9 | Noise level (dba) | 69.4 |

10 | Fan | Mild steel light Weight Straight leaf design |

11 | Inlet | Ø98 mm with flange |

Client: Large Manufacturing Company Specializing in Metal Products

Industry: Metal Products Manufacturing

Problem:

The client was experiencing significant challenges with its powder coating booth. Powder coating, known for its durability and high-quality finish, requires a controlled environment to ensure optimal results. However, the existing ventilation and filtration system in the booth were underperforming, leading to several issues:

Objectives:

Solution:

Cleantek upgraded the powder coating booth by installing a high-capacity blower system designed to significantly enhance suction airflow and improve overall filtration efficiency.

Key Features of the Cleantek Blower System:

Implementation:

The high-capacity blower system was installed and integrated into the client’s existing powder coating booth. Comprehensive training was provided to ensure efficient operation and maintenance of the new system.

Results:

Measurable Impact:

Conclusion:

The successful implementation of Cleantek's high-capacity blower system transformed the powder coating operation, delivering tangible benefits in product quality, worker safety, operational efficiency, and environmental compliance. This case study highlights the critical role of effective airflow and filtration in industrial processes and demonstrates how targeted investments in technology can drive significant improvements across multiple dimensions.